The landscape in the welding industry is changing. We know how to guide you into the new era. Armed with years of experience and deep subject matter expertise, we provide solutions that meet all requirements and methods such as arc welding, laser welding, collaborative robots, MIG/MAG, SMAW, TIG, and many others.

Enhanced Accuracy and Consistency:

Robotic welding ensures accuracy and consistency in every job. With advanced sensors, precise motion control, and intelligent programming, robotic systems consistently deliver high-quality results. Human errors are eliminated, ensuring the highest degree of welding quality, resulting in increased reliability and reduced rework.

Increased Efficiency and Productivity:

Robotic welding significantly boosts efficiency and productivity. Robots work tirelessly without breaks or fatigue, delivering quality results at a faster pace. Automating welding processes maximizes production efficiency and reduces overall cycle times. This enables you to handle time and volume-demanding projects with ease.

Improved safety:

Worker protection is our top priority. Using robots reduces the need for human intervention in hazardous welding environments, minimizing the risk of injuries and exposure to harmful fumes, and enhancing workplace safety.

Cost efficiency:

By automating the welding process, we minimize labor costs and increase productivity. The reduction in job repetitions and improved weld quality also eliminates material waste. Precise control of robotic systems optimizes the use of consumables, leading to cost-effective welding operations.

Contact us today to discover how our expertise and cutting-edge solutions can transform your welding operations and propel your business to new heights of success.

We combine advanced technology, experience, and expertise to deliver the best practices and solutions in the industry.

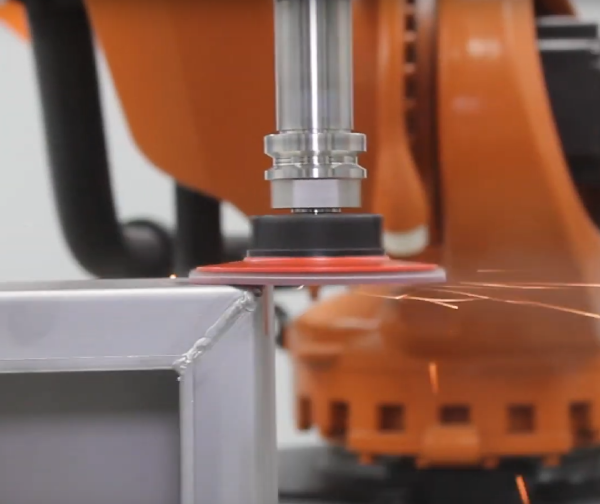

Advanced robotic technology eliminates human error, ensuring precise and uniform grinding results as desired

Robotic grinding optimizes speed and efficiency, with robots tirelessly working without breaks, reducing production time. Meeting tight deadlines and handling high-volume orders becomes achievable without compromising quality.

Safety is paramount in any industrial environment, and robotic grinding reduces potential risks. Minimizing human intervention, robots contribute to a safer working environment with strict adherence to safety protocols.

Robotic grinding offers significant cost savings in the long term. Automating grinding operations reduces the need for manual labor, leading to cost reductions. The consistent quality achieved through robotic grinding minimizes material waste, further improving overall costs

Our team comprises specialized engineers and technicians with profound knowledge and experience in robotic automation and grinding technologies. Working closely with you, we understand your needs and design customized solutions that maximize efficiency and deliver exceptional results.

We design and implement customized robotic palletizing systems that fully meet your requirements.

Robotic palletizing systems significantly boost productivity by automating the palletizing process. Eliminating manual labor constraints ensures seamless operation, leading to faster palletizing cycles, higher throughput, and efficient production lines.

Robotic systems excel over traditional methods, ensuring accurate placement of products on pallets with advanced sensors and intelligent programming, reducing errors and minimizing product damage.

Robotic palletizing systems are highly flexible and adaptable to various product types, sizes, and packaging specifics. Easily transitioning between different product lines, this flexibility maximizes efficiency and minimizes downtime.

Prioritizing worker safety and well-being, robotic palletizing systems handle heavy lifting and repetitive tasks, reducing the risk of injuries and creating a safer work environment.

Working closely with our clients, we assess their unique needs and challenges, changing the face of the industry in the palletizing process with state-of-the-art robotic systems

These solutions are reshaping industrial process automation and productivity optimization, tailored to excel in diverse industries, from manufacturing and assembly to welding, grinding, and palletizing. With advanced robotics, custom applications offer precision, consistency, and increased efficiency, while reducing human involvement in hazardous tasks for enhanced safety. From repetitive to complex processes, custom robotic applications revolutionize industrial procedures, empowering businesses with heightened efficiency and competitiveness.

Our custom robotic applications are designed to meet your unique needs. Working closely with you, we comprehend your challenges and goals, developing tailored solutions that optimize efficiency and productivity.

By automating repetitive tasks, our solutions significantly reduce work times, allowing your workforce to focus on value-added activities. This leads to improved productivity and cost savings, granting you a competitive edge.

Our solutions automate hazardous or physically demanding tasks, minimizing the risk of injuries and harmful exposure. Adhering to strict safety standards, we create a safer working environment for your workforce.

With over 30 years of investment in innovation and development, we maintain partnerships based on mutual respect and appreciation. Count on us to create the custom application that will transform your business.